The performance of Juxin’s PCD wire drawing dies is unparalleled when it comes to wire drawing precision. For a variety of wire materials, our PCD wire drawing dies are made to offer remarkable endurance and precision. We produce dies that can handle wire sizes from 0.05 mm to 11 mm with micron-level accuracy. The technical details of Juxin’s PCD wire drawing dies, how they can be tailored for particular wire types, and why they are the best option for sectors that require the manufacture of high-quality wire will all be covered in this article.

Achieving Unmatched Precision with PCD Wire Drawing Dies

At Juxin, we manufacture PCD wire drawing dies that offer unmatched precision in every aspect of the wire drawing process. The unique structure of PCD dies—composed of micron-sized diamond particles—ensures extreme hardness and resistance to wear. This precision enables our PCD drawing dies to maintain accurate wire diameter and shape, even during high-speed drawing operations.

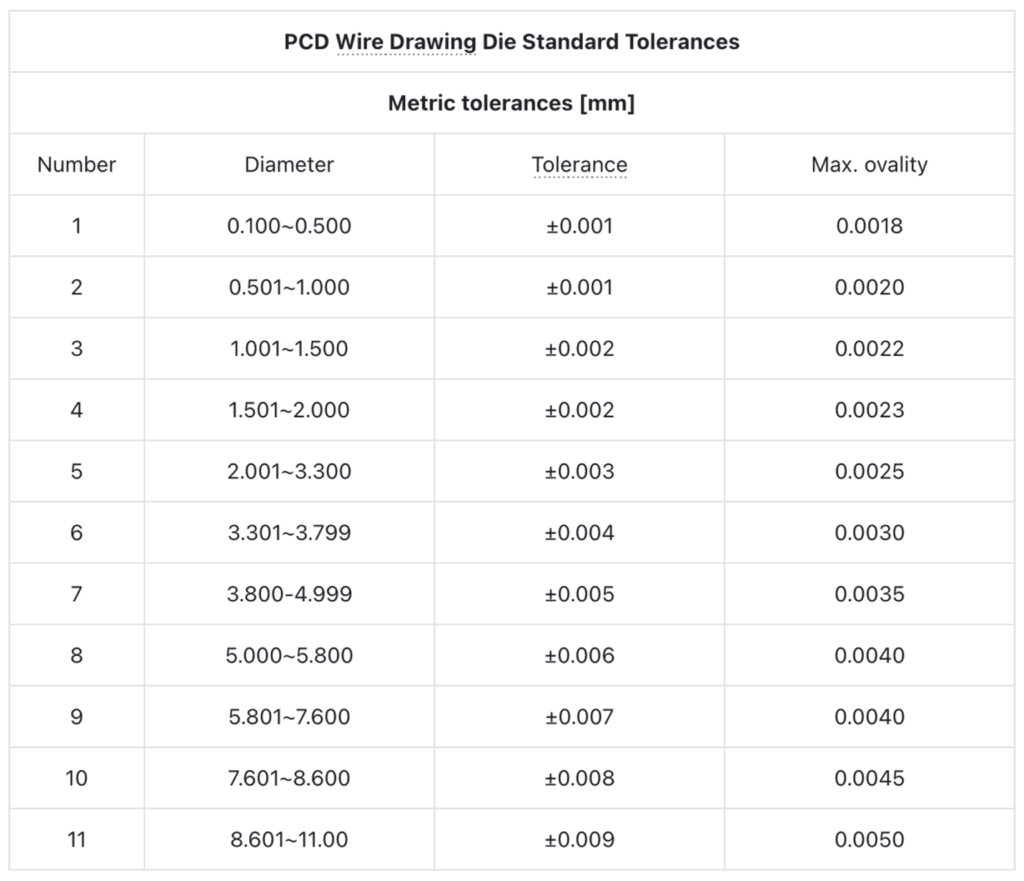

The tight tolerances provided by PCD wire drawing dies ensure that the wire diameter remains consistent throughout the entire drawing process. This is crucial in industries like telecommunications, medical devices, and automotive, where high-precision wires are essential. By using Juxin’s PCD dies, manufacturers can expect to produce wire with smooth surfaces and uniform geometry, reducing defects and improving overall quality.

Tailored Solutions for Different Wire Materials and Diameters

Not all wire materials are the same, and each requires a different type of die to achieve optimal performance. That’s why we offer customized PCD wire drawing dies tailored to specific materials like tungsten wire, aluminum wire, galvanized steel wire, and coated steel wire. Whether you need a die for high-strength materials or a specialized wire, Juxin’s team can modify the design of our PCD dies to meet your exact needs.

Our PCD wire drawing dies are available in a variety of hole sizes, from 0.05 mm to 11 mm, allowing us to accommodate a wide range of wire diameters and materials. This flexibility ensures that our PCD dies are suitable for diverse applications, from drawing fine copper wire for electronics to producing high-strength steel wire for industrial use.

Long-Term Performance and Cost-Effectiveness

When you choose Juxin’s PCD wire drawing dies, you’re investing in a solution that not only delivers precision but also provides long-term value. The durability of PCD dies means fewer replacements and less downtime, which reduces maintenance costs and improves overall productivity. The hardness of PCD dies allows them to withstand the rigors of high-speed wire drawing operations, ensuring that they maintain their performance even after long production runs.

In addition to durability, the wear resistance of PCD wire drawing dies contributes to better wire quality, as there is less chance of wire breakage or surface defects. By using PCD dies, manufacturers can save on both maintenance and replacement costs while also improving the consistency and quality of their wire products.

Conclusion

In conclusion, for producers seeking to obtain exact wire diameters and consistent quality, Juxin‘s PCD wire drawing dies provide a dependable, high-performance option. Our PCD dies are ideal for a range of wire materials, such as copper, aluminum, stainless steel, and more, and can handle wire diameters ranging from 0.05 mm to 11 mm. Juxin’s proficiency and commitment to excellence make us a perfect partner for attaining the best wire drawing outcomes, whether you require standard solutions or bespoke PCD dies. For PCD wire drawing dies that offer accuracy, longevity, and long-term cost benefits, go with Juxin.