High-precision single crystal diamond dies, which are utilized for wire drawing with unparalleled accuracy, are our specialty at Juxin. Wire diameters between 0.05 mm and 11 mm can be used with our dies, which are made with micron-level accuracy. Since every industry has different requirements, we also provide specialized SCD wire drawing die materials and solutions to make sure you receive just what you need for your production process.

The Structure of Single Crystal Diamond Dies: A Step Above

Single crystal diamond dies are constructed using a highly polished natural or synthetic diamond core. The diamond core is mounted into a stainless steel casing, providing a durable structure for the die. These dies are unparalleled in terms of their hardness, with the single crystal diamond offering outstanding wear resistance and structural stability, making them the ideal choice for drawing wires with high precision.

Because of the superior hardness of the diamond material, SCD wire dies are able to maintain their shape and perform consistently for extended periods. Whether you’re drawing ultra-fine wires or heavy-duty materials, our single crystal diamond dies deliver exceptional surface finishes and consistent performance over time.

Unmatched Precision: The Role of Tolerances in Wire Drawing

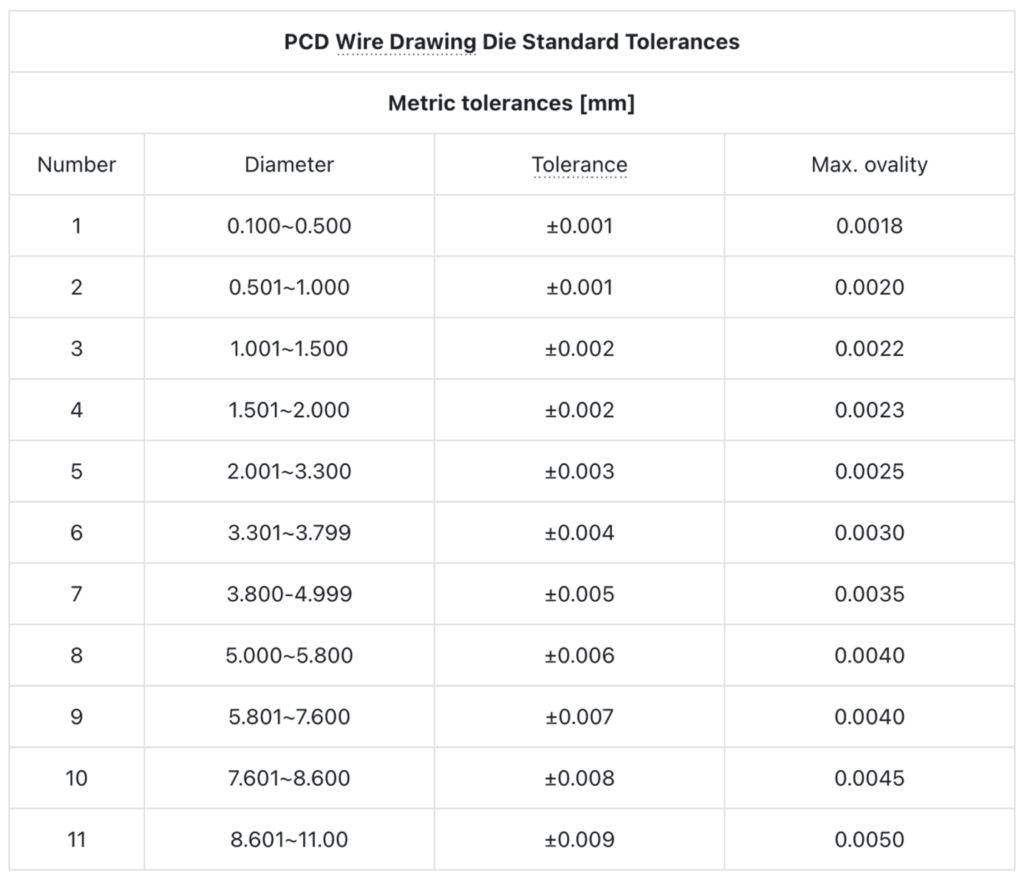

One of the defining characteristics of Juxin’s single crystal diamond dies is their precision. These dies can handle wire diameters from 0.05 mm to 11 mm, and the tolerances we achieve in the manufacturing process are incredibly tight, with micrometer-level accuracy. The aperture tolerance for our dies is ±0.002μm, allowing for the smoothest, most consistent wire drawing processes, even for very fine wires.

This precision ensures that the wire’s surface is smooth, round, and flawless—qualities that are critical in industries that require high-performance wire, such as bonding wire (gold, copper, aluminum) and EDM wire. At Juxin, we’re able to achieve these tight tolerances because of our advanced R&D platform and the expertise of our engineers, who apply years of experience to create the best possible wire dies.

Applications Across Multiple Industries

Our single crystal diamond dies are used in a wide range of industries, from automotive to telecommunications, thanks to their ability to handle fine wires with incredible accuracy. In the electronics industry, for instance, SCD wire dies are used to create bonding wires made of gold, copper, and aluminum, ensuring superior wire quality and smoothness.

The structural stability of our SCD wire dies makes them ideal for applications that demand high levels of performance, such as wire drawing for high-frequency cables, medical devices, and optical fibers. At Juxin, we tailor our dies to suit the needs of each client, providing solutions that align with their specific wire drawing requirements.

Conclusion

Single crystal diamond dies from Juxin provide unparalleled accuracy, dependability, and adaptability. Our SCD wire dies produce perfect wire drawing results for a wide range of applications with micron-level tolerances and the capacity to handle wire diameters ranging from 0.05 mm to 11 mm. Our dies provide consistency, roundness, and smoothness every time, whether you’re working with ferrous or non-ferrous wires. For the best single crystal diamond dies customized to your specifications, rely on Juxin.