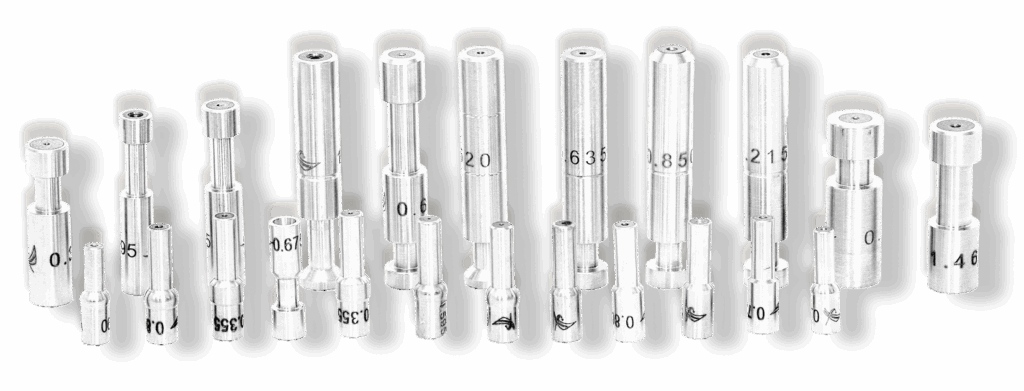

PCD Enameling Die

Juxin precision enameling dies are exclusively engineered for round wire applications, spanning ultra-fine 0.1mm conductors to heavy-duty wires exceeding 5mm diameter. Wire enameling dies are used to achieve industry-leading coating uniformity through precise thickness control, forming perfectly concentric insulation layers with minimal material leakage.

Hole Sizes for Enameling Die

Available: 0.1mm to 7.6mm

We have ready stock for immediate delivery.

Coating Compatibility with Enameling Dies

Different insulation materials require specific die properties for optimal coating results. Contact us now for a free solution to your application needs.

Enameling drawing die with Polyester requires smooth die surfaces (Ra <0.1μm) to prevent viscosity-driven streaks. Consistent coating at high speeds (up to 50m/s), reducing pinhole defects

Choose PEI as your enameling die coating needs thermal–stable dies (350°C+) to handle high-cure temperatures.

Wire enameling die compatibility with PAI is widely used for aerospace harnesses, it always requires ultra-hard dies (HV > 3000) to resist abrasive fillers.

Benefits of Wire Enameling Die:

- Ultra-smooth and uniformity enamel finish: The enameling die ensures a mirror-like surface finish by precisely controlling enamel flow dynamics, critical for high-frequency applications.

- Precise coating concentricity: Wire enameling die technology maintains concentricity within 0.3% tolerance through balanced pressure distribution, eliminating electrical weak spots.

- Long die life and wear resistance: Made with advanced materials such as PCD, the PCD enameling die offers outstanding wear resistance and a longer service life, minimizing downtime and replacement costs.

- Minimal enamel buildup and leakage: The optimized design of enameling dies for round conductors minimizes enamel accumulation and prevents leakage, ensuring clean, stable, and uninterrupted production.

- Compatible with all major enamel types: Our wire enamel wire die is engineered to handle a wide range of enamel types, including polyester, polyurethane, and polyimide without compromising performance or lifespan.

- Minimal variation in finished product diameter after enameling: Using a high-precision enameling drawing die allows for tight control over coating thickness, ensuring minimal variation in final wire diameter for high-spec applications.

- Cost efficiency: Juxin enameling die with superior durability and high precision, reducing material waste and maintenance frequency.

Applications:

- Copper wire for motors, transformers, and coils

- Aluminum wire in lightweight transformer

- and automotive coils

- Copper alloys (e.g. CuMg, CuSn) for high-strength or high-temp windings

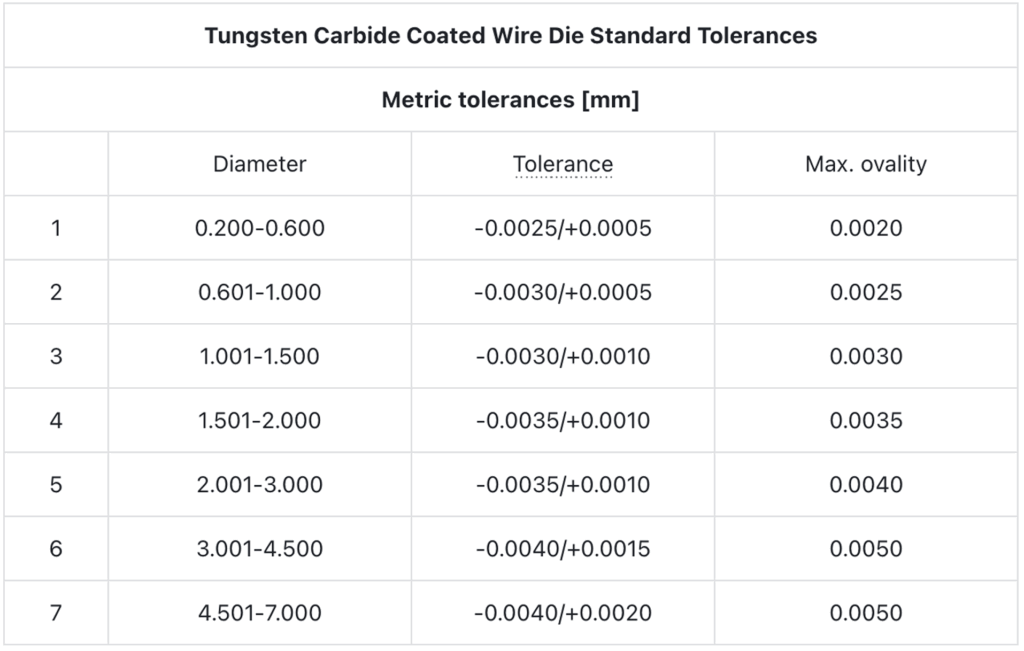

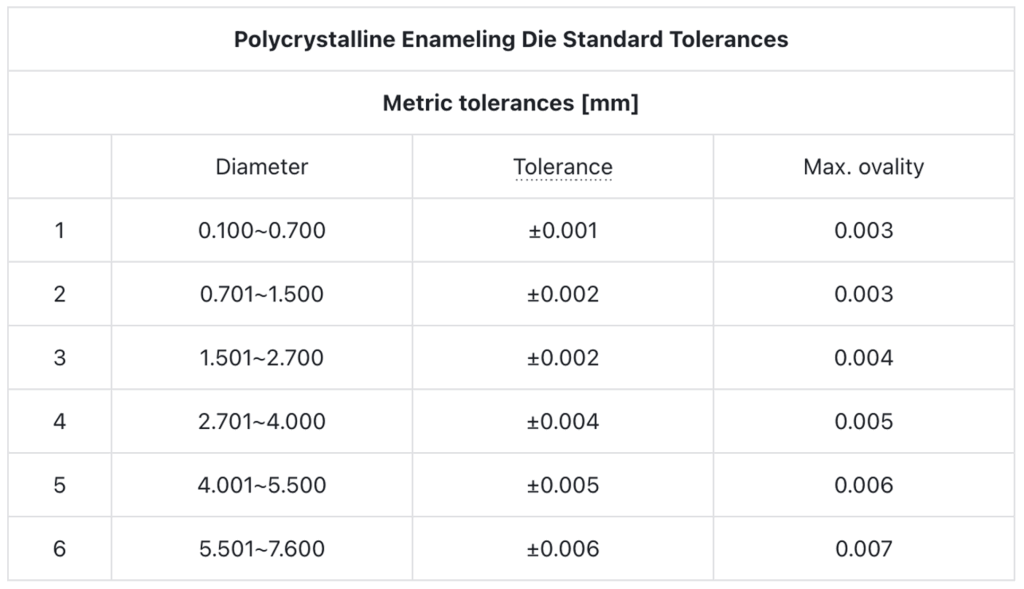

Technical Specifications

*Available size range: 0.1mm to 7.6mm (We support customization in feeding materials)

Machine Types:

Horizontal & Vertical enameling lines

Operating Temp:

Stable under 250–300°C enamel curing

Surface Finish:

Mirror-polished bore for optimal flow

Why Choose Juxin for your Enameling Die?

- 30+ Years in Enameling Die Manufacturing

- Stable Enameling Die & Wire Drawing Die Supply Chain

- Enameling Die with High Quality & Affordable Price

- Free Enameling Die Quote & Fast Global Delivery

FAQs

What is enameling dies?

An enameling die is a precision tool used in the production of insulated magnet wires. Commonly made with durable materials like PCD, a PCD enameling die ensures uniform enamel coating and high wear resistance. These tools are essential for applying insulation to copper or aluminum wires, particularly when enameling dies for round wire applications.

How does wire enameling die work?

A wire enameling die works by guiding the bare wire through a calibrated aperture while it passes through a liquid enamel bath. The enamel drawing dies meters and wipes off excess enamel, ensuring a consistent coating thickness. Afterward, the wire enters a curing oven, where it produces a smooth and durable insulation layer. High-performance wire enamel wire die systems help maintain coating accuracy, reduce waste, and improve electrical performance.

Place your RFQ request online to see how our Enameling Dies can help improve the quality of your wire

Place your RFQ request online to see how our Enameling Dies can help improve the quality of your wire