Enameling Dies for round wire

Delivering uniform insulation builds and reliable performance in applications ranging from fine magnet wires to heavy-duty coil wires

Coating Compatibility

Smooth, Inert Die Surface:

The PCD insert’s chemically inert, ultra-smooth surface allows various enamel types to flow through without reacting or sticking.

Benefits

- Ultra-smooth and uniformity enamel finish

- Precise coating concentricity

- Long die life and wear resistance

- Minimal enamel buildup and leakage

- Compatible with all major enamel types

- Minimal variation in finished product diameter after enameling

- Cost efficiency

Applications

- Copper wire for motors, transformers, and coils

- Aluminum wire in lightweight transformer and automotive coils

- Copper alloys (e.g. CuMg, CuSn) for high-strength or high-temp windings

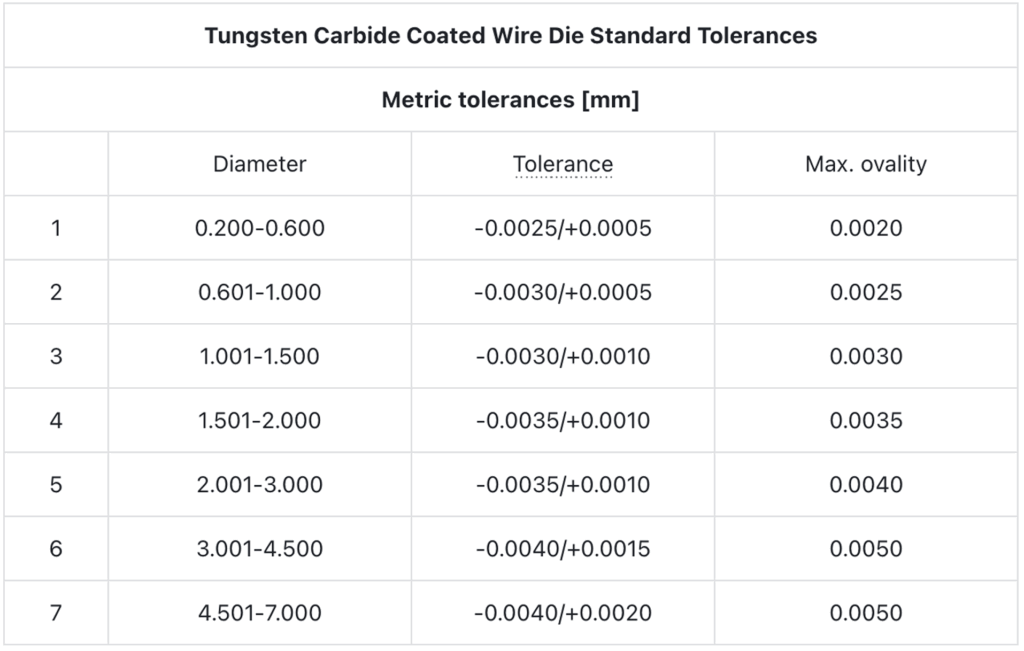

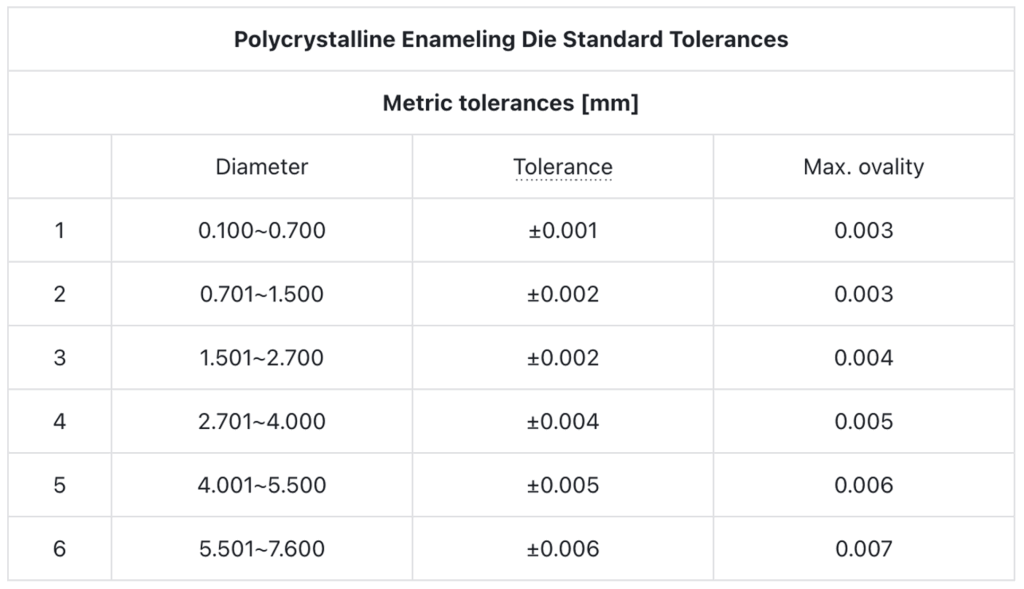

Technical Specifications

*Common feeding range of raw materials: 0.09–11m (We support customization in feeding materials)

*Stricter tolerances can be provided when required

Machine Types:

Horizontal & Vertical enameling lines

Operating Temp:

Mirror-polished bore for optimal flow

Surface Finish:

Horizontal & Vertical enameling lines

Why Juxin:

Juxin Enameling Die Assemblies – engineered with PCD or tungsten carbide inserts in durable steel casings – deliver precision insulation coating for magnet wires. Critical to high-speed horizontal/vertical production lines, these dies feature calibrated apertures that meter and wipe liquid enamel to exact thicknesses before curing, ensuring uniform insulation, enhanced electrical performance, and reduced material waste for cost-effective, high-quality output.

Place your RFQ request online to see how our PCD dies can help improve the quality of your wire

Place your RFQ request online to see how our PCD dies can help improve the quality of your wire