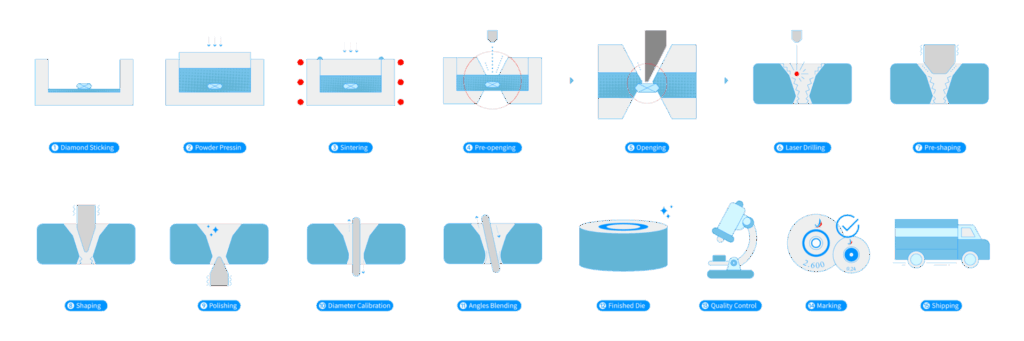

We at Juxin are proud of our proficiency in developing wire drawing solutions for diamond dies that offer outstanding performance. The production of precision diamond dies wire drawing is a complex process that includes 15 essential processes to guarantee that every die satisfies the highest requirements for performance, accuracy, and durability. We’ll examine the manufacturing process of these sophisticated dies in greater detail in this post, including everything from diamond sticking to final inspection and delivery.

Diamond Sticking: The Foundation of Durability

The journey to creating high-performance diamond dies wire drawing begins with diamond sticking. In this first step, diamonds are carefully placed on a metal substrate to form the core of the die. This is crucial because the diamonds will eventually become the tool’s cutting edge, which needs to handle extreme wear. By ensuring that each diamond is securely attached, we lay the foundation for a durable die that will perform well under demanding conditions.

Sintering and Shaping: Ensuring Strength and Precision

Once the diamonds are in place, we move on to the sintering process. During sintering, high heat is applied to fuse the diamonds and substrate, ensuring that the die has the necessary structural integrity. This step is followed by pre-opening to start the process of forming the die’s shape. Our team carefully monitors this stage to ensure that the diamonds are embedded securely and aligned correctly for optimum performance.

Following pre-opening, the die undergoes opening, where we begin to refine the die shape to match the required specifications. Precision at this stage ensures that the diamond dies wire drawing process will produce wire with a perfect finish and consistent diameter, crucial for industries like medical and microelectronics.

Laser Drilling, Polishing, and Final Calibration

Once the diamond dies wire drawing starts to take shape, we employ laser drilling to create the specific hole sizes required for wire drawing. This high-tech approach ensures that we maintain micron-level accuracy, which is essential for high-precision wire production. After drilling, the dies undergo pre-shaping, followed by shaping to achieve the precise dimensions needed for effective wire drawing.

The die is then polished to ensure a smooth, flawless surface. This ultra-smooth finish helps reduce friction during the wire drawing process, resulting in high-quality wire with fewer defects. The final touches include diameter calibration and angle blending, ensuring that every aspect of the die performs with precision.

Conclusion

In summary, the production of diamond dies wire drawing is a multi-step, intricate procedure that demands accuracy at every turn. Every stage, from polishing to diamond adhering, affects the die’s longevity and performance. At Juxin, we make sure that our wire drawing solutions for diamond dies are made to the highest standards of quality, producing wire with exceptional results. Juxin is the reliable option for your wire drawing requirements because of our team’s dedication to giving you dies that optimize productivity, minimize downtime, and ensure constant wire quality.