SCD wire dies, which are designed for utmost durability and precision, are our specialty at Juxin. Our cutting-edge procedure consists of 15 painstaking processes that are intended to guarantee that each SCD wire die performs exceptionally well. We are able to produce wire dies with exceptional surface finishes, precise wire management, and higher hardness by utilizing 111-facet orientation diamonds. With an aperture tolerance of ±0.002μm, our SCD wire dies are perfect for applications involving ultra-fine wires, which typically have a diameter of less than 0.01mm.

Step-by-Step Crafting of SCD Wire Dies: The Beginning

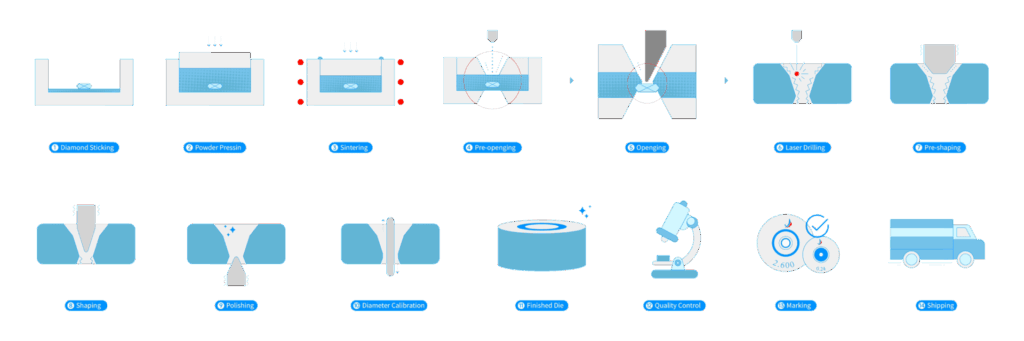

The first step in manufacturing our SCD wire dies starts with diamond sticking. This process uses premium materials to ensure that each die’s base has a strong foundation for further shaping. Following this, we proceed with powder pressing, which sets the structure of the die, preparing it for the intricate procedures to come. After that, sintering and pre-opening help refine the die’s core, ensuring it’s ready for the precision drilling needed in the later stages.

Precision Hole Processing and Calibration

As we move to the next phase, the core of the SCD wire die undergoes laser drilling, a critical step that ensures the hole’s alignment and precision. Our technology guarantees that each die is shaped to within extremely tight tolerances. The pre-shaping stage follows, which further refines the aperture and adjusts its shape to fit specific wire drawing needs.

Next, we calibrate the diameter and ensure that the SCD wire die aligns with the required specifications for the wire being drawn. These steps are critical for guaranteeing the precise control of the wire’s dimensions during the drawing process.

Fine-Tuning and Final Quality Control

In the final steps, we focus on the angles and blending and shaping processes to ensure the die achieves its final form. These stages allow us to perfect the die’s geometry, optimizing it for performance in specific wire types, including bonding wires like gold, copper, and aluminum. Once polished, each SCD wire die undergoes rigorous quality control testing to ensure that the die performs flawlessly in demanding applications like EDM wire production.

Our team takes great care to ensure that all SCD wire dies meet stringent international standards. The last step involves marking and shipping, where each die is packaged and ready for use in industries that require the utmost precision and durability.

Conclusion

Our goal at Juxin is to create the best SCD wire dies. Our 15-step procedure is developed to create dies that not only fulfill but also surpass industry standards. We guarantee that every die is a wire control masterpiece, perfect for ultra-fine wires and high-performance applications, from the first diamond to the last shipment. You can depend on Juxin for exceptional accuracy and dependability in each SCD wire die, regardless of whether you’re working with ferrous or non-ferrous wires.