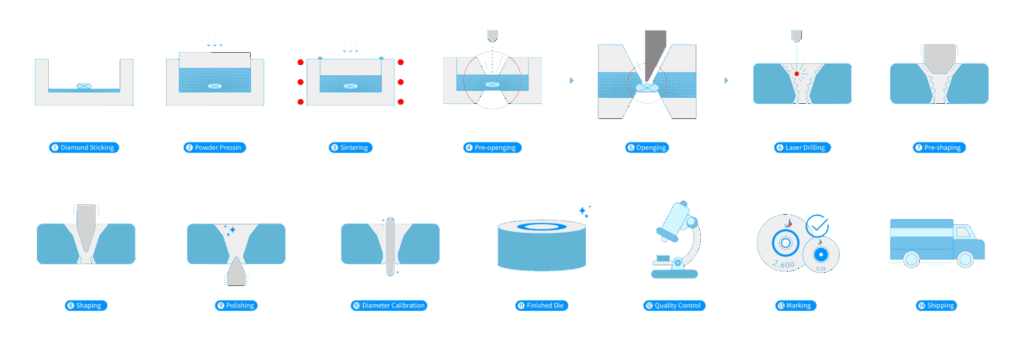

Our area of expertise is manufacturing PCD drawing dies that offer exceptional accuracy and dependability for wire drawing applications. Our 14-step, meticulously regulated process for creating PCD drawing dies guarantees that every die performs to the highest standards. These dies are designed to provide outstanding durability and wear resistance, which makes them ideal for sectors like copper, tungsten, and stainless steel wire that demand reliable, high-quality wire drawing. This article will guide you through the crucial processes that go into making PCD drawing dies and how each one affects how effective they are as a whole.

Diamond Sticking and Sintering: Laying the Foundation

The process of making PCD drawing dies begins with diamond sticking, where fine diamond particles are carefully arranged on a metal substrate. This is followed by powder pressing, where the diamond particles are bonded with a metallic agent. The mixture is then sintered under extreme heat and pressure to form a solid, durable die. This step is essential for creating a die that can withstand the mechanical stresses of wire drawing, as it provides the necessary hardness and resistance to wear.

The combination of diamond particles and the sintering process ensures that the resulting PCD drawing dies are capable of drawing wire with minimal degradation over time, providing manufacturers with a tool that will last through extended production runs.

Shaping and Calibration: Achieving Micron-Level Precision

Once the die blank is prepared, we move on to shaping it into the precise geometry needed for wire drawing. The pre-opening and opening stages are crucial for shaping the die and ensuring that it aligns with the required wire diameter. After shaping, the die undergoes laser drilling, which allows us to achieve highly accurate hole sizes, ensuring that the wire will be drawn smoothly and consistently through the die.

At Juxin, we place great emphasis on achieving micron-level accuracy with our PCD drawing dies, which is essential for producing wire with a uniform diameter and smooth surface. This precision is critical in industries like medical device manufacturing, where even the smallest variation in wire dimensions can lead to performance issues.

Polishing and Final Quality Checks: Ensuring Top-Notch Performance

After the die is shaped, it undergoes a polishing process to remove any surface imperfections and ensure a smooth finish. This is important for reducing friction during the wire drawing process, which helps prevent wire defects and prolongs the life of the die. We also perform diameter calibration to ensure that the die is perfect for the specific wire size being drawn.

Finally, our team conducts rigorous quality control checks to ensure that each PCD drawing die meets our strict standards. We test for durability, accuracy, and consistency, ensuring that the dies will perform optimally even under the most demanding production conditions.

Conclusion

Every stage of Juxin‘s PCD drawing die manufacturing process, from polishing and quality control to diamond sticking and sintering, requires precision. Every step helps to produce a die that offers exceptional durability, accuracy, and performance. Our PCD drawing dies provide outstanding wire quality and long-lasting results, making them ideal for high-precision wire applications. For all of your wire drawing requirements, rely on Juxin’s experience and knowledge to deliver the best PCD drawing dies.