SCD drawing die

Juxin single crystal diamond (SCD) wire dies use 111-facet orientation diamonds that offer superior hardness, excellent surface finish, and precise wire control. They are ideal for ultra-fine wires under 0.01mm, with an aperture tolerance within ±0.002μm. As SCD wire die features high-temperature resistance, they are also widely used in both ferrous and non-ferrous wire drawing industries, such as bonding wire (gold, copper, aluminum), EDM wire, and more.

SCD Wire Die Hole Sizes

Available: 0.03mm to 11.0mm

We have ready stock for immediate delivery.

Features

- Made from 111-oriented diamonds

- Predictable wear patterns

- Predictable maximum recut size

- Long Die Life & Recutting Ability

- High temperature resistance

- Optimized for High-Value Metals

Applications

- Bonding wire (gold, copper, aluminum)

- Medical wire(stainless steel or nitinol fine wires)

- EDM wire

- Ultra-fine coaxial wires(Communication & electronics)

- Alloy and specialty wires(nickel alloys, tungsten or molybdenum fine wires platinum thermocouple wires, etc.)

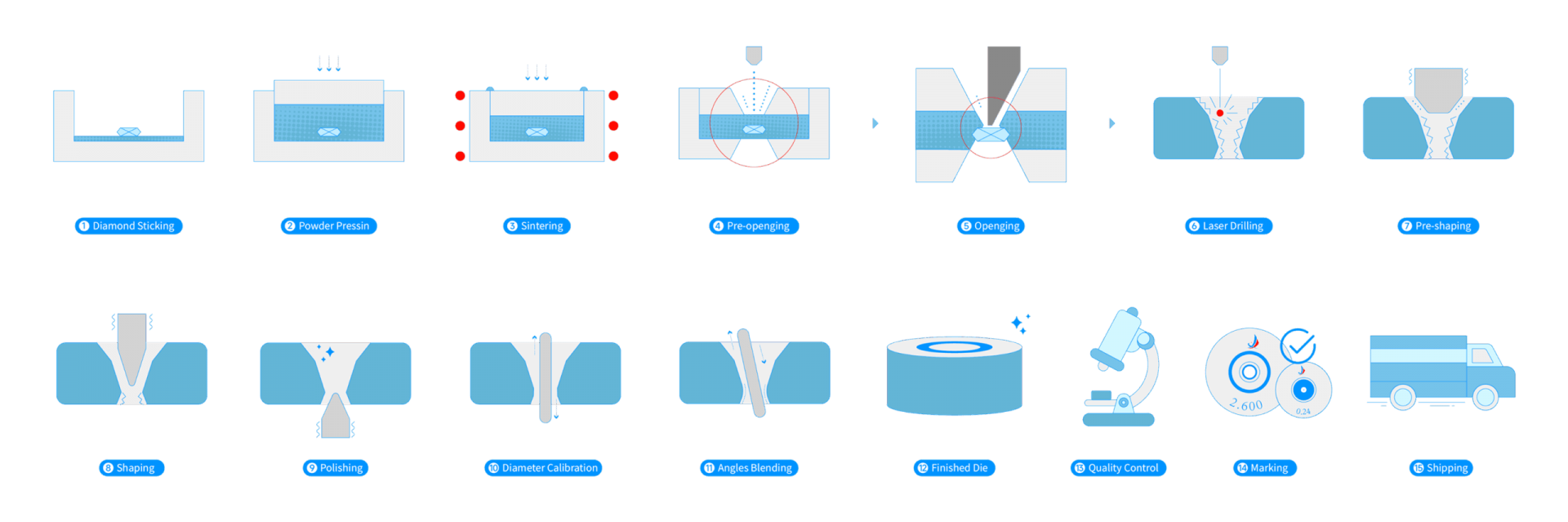

How SCD drawing Dies Are Made

Juxin manufactures high-precision SCD wire drawing dies through a 15-step process, including Blank Manufacturing, Hole Processing, and Finishing.

Discover how each step works together to ensure the exceptional quality and precision of every single crystal diamond die.

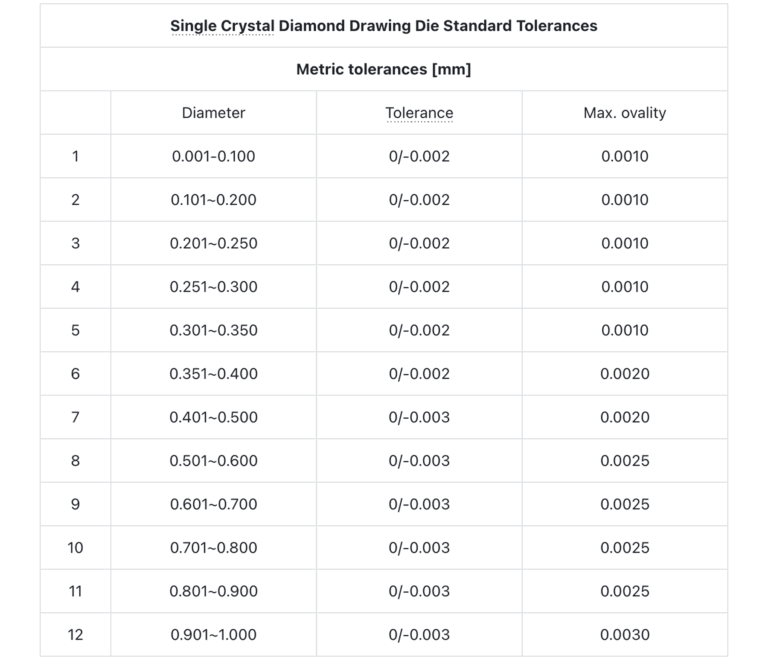

Technical Specifications

Refer to the table below for the standard tolerances of SCD wire dies. Juxin produces single crystal diamond drawing dies with micron-level precision, suitable for wire diameters from 0.05 to 11 mm. We also offer customized SCD wire drawing die materials and solutions tailored to your unique needs.

*Available size range: 0.05–11mm (We support customization in feeding materials)

Compatible Materials

Single-crystal diamond drawing dies are ultra-precision wire drawing tools constructed with a highly polished natural or synthetic diamond core mounted in a metal casing (usually stainless steel). They are used to draw wire down to extremely fine diameters with exceptional accuracy and surface quality. With unmatched hardness and structural stability, diamond die wire drawing delivers excellent wear resistance, consistent performance, and the finest surface finish available in wire drawing applications. Wire drawn through a diamond drawing dies to achieve virtually flawless smoothness and consistent roundness, even at micrometer sizes.

FAQs

1. What is the benefit of SCD drawing die?

An SCD drawing die offers multiple advantages over traditional wire drawing tools. Thanks to the extreme hardness and wear resistance of single crystal diamond dies, they deliver outstanding dimensional accuracy and a mirror-like surface finish, even when drawing ultra-fine wires.

2. What materials can be processed using an SCD drawing die?

SCD drawing dies are ideal for drawing a wide range of compatible materials, such as copper, gold, silver, platinum, stainless steel, and other non-ferrous metals. They are particularly effective when used as a single crystal diamond die for fine wire, providing unmatched consistency for industries like electronics, aerospace, and medical devices.

3. How long does an SCD drawing die typically last?

The lifespan of an SCD drawing die can vary depending on the wire material, drawing speed, and lubrication conditions. Under normal operating conditions, Juxin high-quality single-crystal diamond die can typically last for 20,000 to 100,000 meters of wire drawing, sometimes even more when processing softer materials like gold or copper. However, the specific lifespan also depends on how you maintain the SCD drawing die. Proper cleaning, correct alignment, and regular inspection can significantly extend the service life of SCD wire dies.

Place your RFQ request online to see how our SCD Drawing Dies can help improve the quality of your wire

Place your RFQ request online to see how our SCD Drawing Dies can help improve the quality of your wire