Polycrystalline Diamond (PCD) Drawing Die

Juxin has been a professional for PCD die manufacturers for over 30 years. Each PCD die is sintered from micron-sized diamond particles and a bonding agent under high-temperature and high-pressure conditions. PCD wire dies are featured by exceptional hardness, superior wear resistance, and strong impact resistance. They are commonly used in the manufacturing of copper wire, aluminum wire, stainless steel wire, welding wire, and various non-ferrous metal wires.

PCD Die Hole Sizes

Available: 0.03mm to 11.0mm

We keep a full stock of PCD wire drawing dies available for immediate delivery.

Features

- Durability surpasses TC, SSCD & ND dies

- Suitable for long-term production runs

- Excellent for wires in high corrosive environment

- Maintains wire shape even under severe die wear

Applications

Copper wire, aluminum wire, tungsten wire, molybdenum wire, stainless steel wire, coated steel wire, welding wire, galvanized steel wire, saw wire

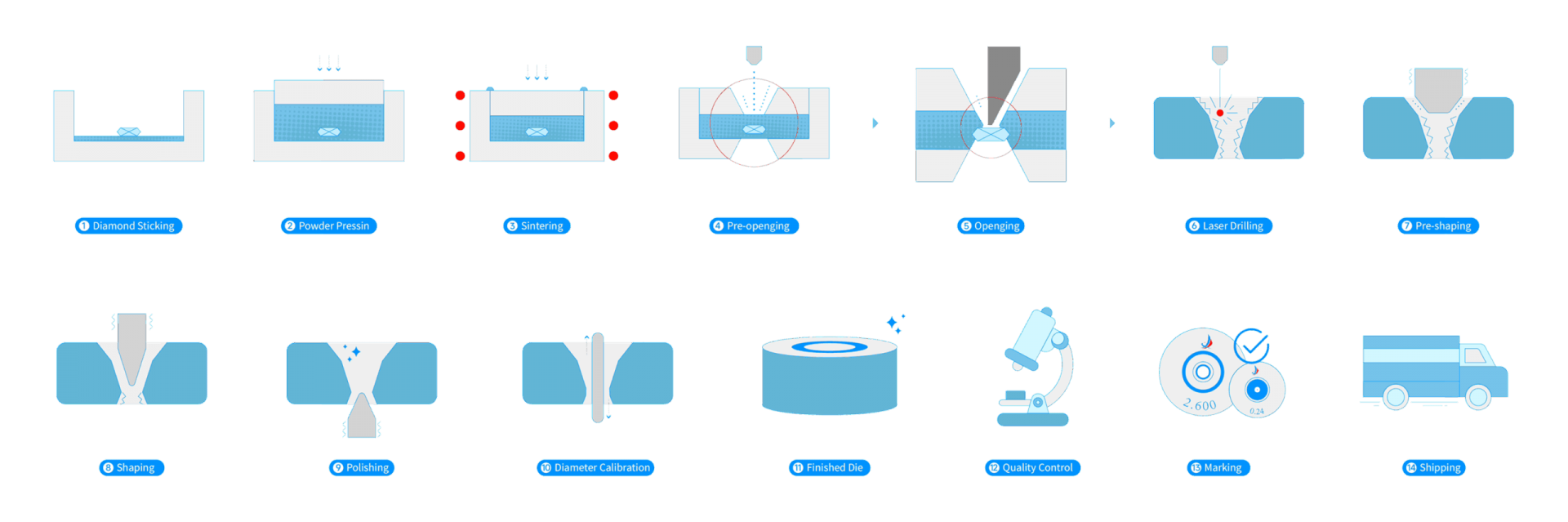

How PCD Drawing Dies Are Made

Producing a high-durability PCD wire drawing die involves 14 critical steps, including Blank Preparation, Die Shaping, and quality assurance. Explore the flowchart to see how each detail contributes to crafting PCD wire dies.

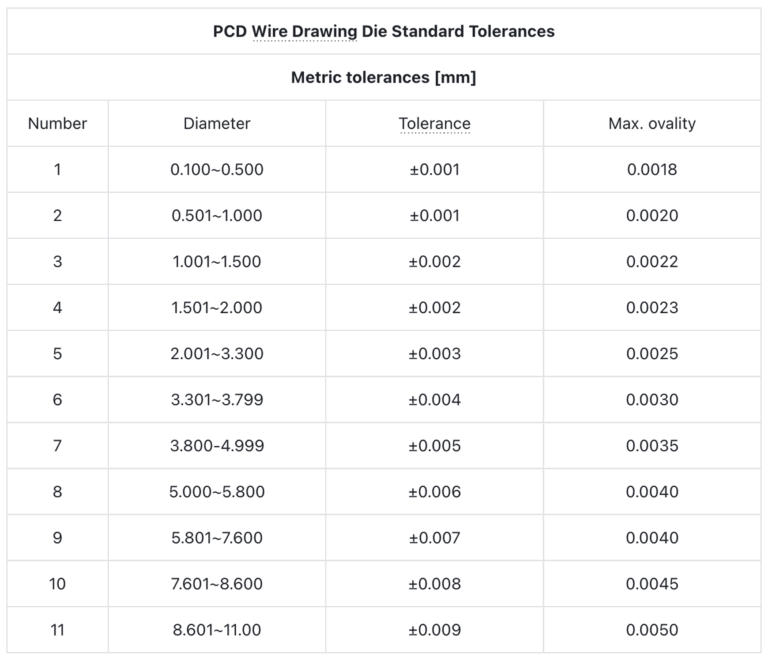

Technical Specifications

View the table below to learn the standard tolerances of PCD wire dies. Juxin manufactures PCD drawing dies with micron-level accuracy for wire diameters ranging from 0.05 to 11 mm. We also support customized PCD drawing die-feeding materials and solutions based on your specific requirements.

*Available size range: 0.05–11mm (We support customization in feeding materials)

Compatibility of PCD wire dies:

Suitable for both wet and dry drawing processes

PCD core Types:

- Self-Supported (Metal-Filled): PCD core without support ring, suitable for various wire drawing applications.

- Tungsten Carbide Supported: PCD core bonded to a tungsten carbide support ring, enhancing die strength and stability.

- Thermally Stable (Metal-Free): Self-supported PCD without metal catalyst, offering superior thermal stability for high-temperature applications.

Grain Sizes Available:

1 µm (ultra-fine), 5 µm (fine), 12 µm (medium), 25 µm (coarse). Selection depends on desired wire surface finish and drawing conditions.

Place your RFQ request online to see how our PCD dies can help improve the quality of your wire

Place your RFQ request online to see how our PCD dies can help improve the quality of your wire

FAQs

1. What are the advantages of PCD drawing dies?

PCD drawing dies are different from traditional dies such as SCD, ND dies in several key aspects, making them the preferred choice for demanding wire drawing applications:

Exceptional Durability: PCD dies are significantly more wear-resistant than carbide (TC), single-crystal diamond (SCD), or natural diamond (ND) dies, ensuring a much longer service life even under high-stress conditions.

Ideal for Long Production Runs: PCD wire dies have extreme hardness and thermal stability, maintaining consistent performance over extended periods, reducing downtime and increasing productivity.

Superior Corrosion Resistance: Unlike conventional dies, PCD drawing dies can withstand highly corrosive materials (e.g., stainless steel, titanium, and other abrasive wires) without degrading, making them perfect for specialty wire manufacturing.

Stable Wire Shape Retention: Even when the PCD die experiences wear, the drawn wire retains its precise dimensions and surface finish, ensuring consistent quality throughout the die’s lifespan.

2. How to maintain PCD dies?

Here are some tips to help maintain and extend the lifespan of PCD drawing dies:

Regular Cleaning: Remove debris and lubricant residues to prevent clogging.

Proper Lubrication: Use high-quality lubricants to reduce wear on PCD wire dies.

Avoid Overheating: Excessive heat can damage PCD wire drawing dies. Monitor the drawing speed carefully.

Storage Protection: Store PCD dies in a dry, dust-free environment to prevent corrosion.

Professional Inspection: Periodically check for wear or cracks to ensure optimal performance.

3. What's the minimum order quantity (MOQ) of your PCD dies?

Juxin PCD wire dies come with no minimum order quantity, providing full flexibility for both small and large orders. As a trusted PCD dies manufacturer, we also offer customized solutions to meet all your exact specifications.