Natural Diamond (ND) Drawing Die

Juxin has been a trusted diamond wire drawing die supplier for over 30 years. Our diamond drawing dies deliver unmatched precision and purity for ultra-fine wire production in critical industries such as microelectronics and medical devices. Diamond dies are ideal for fine and ultra-fine wire applications, offering low surface friction, smooth wire finishes, high drawing performance, and reduced energy consumption.

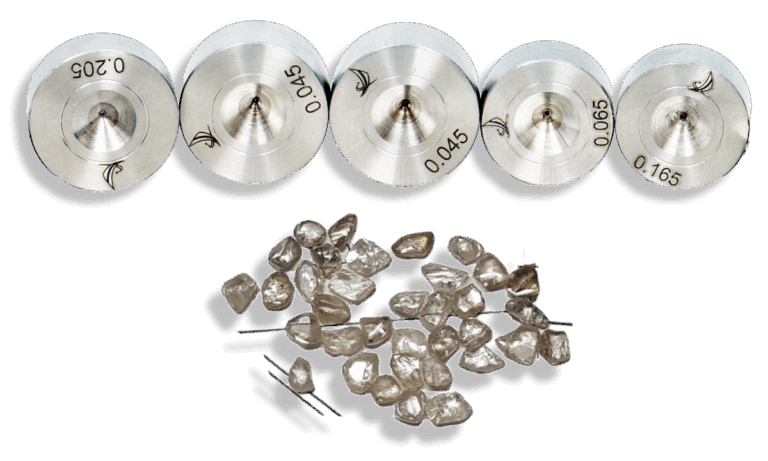

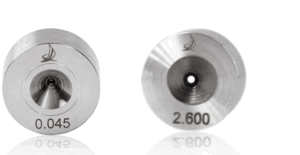

Diamond Die Hole Sizes

Available: 0.02mm to 2.6mm

We keep a full stock of diamond dies available for immediate delivery

Features

- Ideal for fine and ultra-fine wire

- Low surface friction

- Smooth wire surface

- Ideal for High-Value Metals

- High drawing performance with low energy consumption

Applications

- Tungsten filament wire

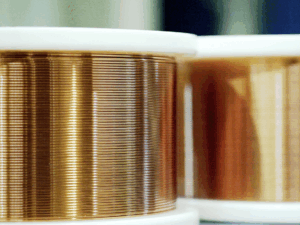

- Bonding wire (gold, copper, aluminum)

- Medical wire

- Stainless steel wire

- Copper wire

- EDM wire

- Special alloy and high-performance alloy wire

- Precious metal wire

- Various other ferrous and non-ferrous metal wire types

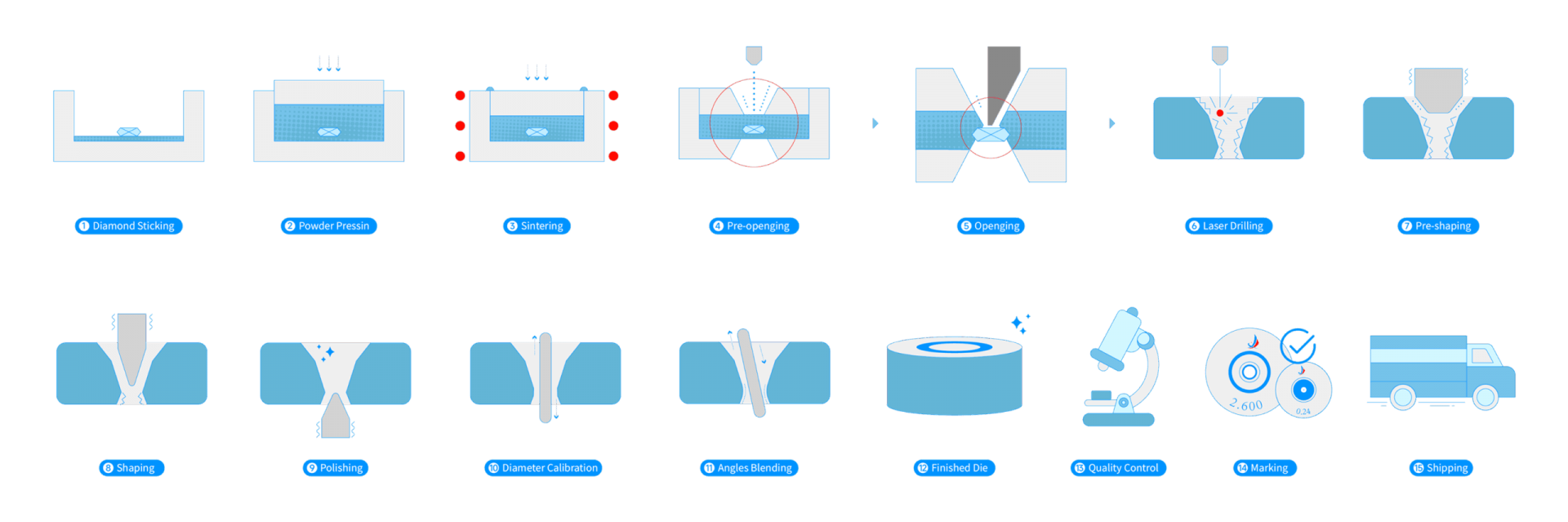

How Diamond Drawing Dies Are Made

Producing a precision diamond die typically involves 15 critical steps. Explore the flowchart to see how each detail contributes to crafting high-performance diamond wire drawing dies

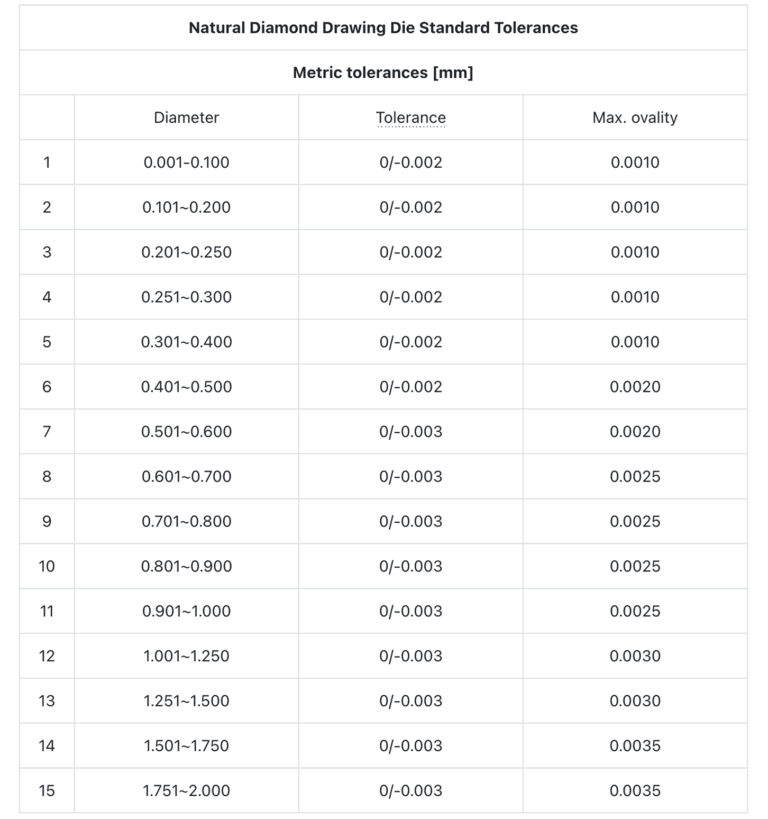

Technical Specifications

Juxin manufactures diamond drawing dies with micron-level accuracy for wire diameters (0.05–11mm), and support custom diamond die solutions for specialized applications.

*Available size range: 0.05–11mm (We support customization in feeding materials)

Diamond Dies are Ideal for High-Value Metals:

Juxin precision diamond dies for wire drawing deliver exceptional performance in processing high-value metals like gold, silver, and platinum. Diamond drawing dies combine ultra-smooth surfaces with micron-level accuracy, minimizing material loss and preserving wire integrity. Whether you require standard or custom wire drawing diamond die solutions, Juxin professional teams offer ND dies that are perfect for producing fine wires from costly metals, while maintaining superior quality and maximizing yield.

Place your RFQ request online to see how our ND Drawing Dies can help improve the quality of your wire

Place your RFQ request online to see how our ND Drawing Dies can help improve the quality of your wire

FAQs

1. How to maintain the diamond drawing dies?

To ensure long service life and optimal performance of your diamond drawing dies, proper maintenance is essential. As an experienced diamond wire drawing dies supplier, we recommend:

· Routine inspection of the diamond dies for wire drawing to identify early signs of wear or cracking.

· Timely re-polishing to maintain surface precision, especially for high-tolerance applications.

· Use of clean lubricants during the drawing process to minimize friction and heat buildup.

· Organized rotation of diamond dies wire drawing units to distribute wear evenly.

· Proper storage in a clean, dry environment to avoid contamination or physical damage.

· Regular maintenance not only extends the life of each diamond die, but also ensures high-quality output throughout production.

2. How do I clean the diamond dies?

Cleaning diamond drawing dies is a critical step in preserving their accuracy and preventing surface damage. We recommend the following cleaning methods for your diamond coated dies:

· Use ultrasonic cleaning with a mild solvent to remove metal debris from the diamond wire drawing die surface.

· Rinse with deionized water or dry with compressed air to prevent chemical residue buildup.

· Avoid abrasive tools that can scratch or damage the delicate surface of the diamond dies.

· Consistent cleaning helps preserve the performance of your wire drawing diamond dies, reduces wire surface defects, and prolongs die life.

3. What are the advantages of wire drawing diamond dies?

Wire drawing diamond dies provide significant advantages over traditional materials such as tungsten carbide. Here are the key benefits of choosing diamond dies:

Exceptional durability: As the hardest known material, diamond offers outstanding resistance to wear and deformation, ensuring reliable performance in demanding environments.

Excellent surface finish: Delivers ultra-smooth wire surfaces, essential for applications requiring high precision and minimal surface defects.

Longer service life: With superior hardness and wear resistance, diamond drawing dies require fewer replacements, helping reduce downtime and overall production costs.

Consistent performance: Maintains stable wire diameter and geometry throughout extended production runs, ensuring consistent quality.

High-speed compatibility: Ideal for modern high-speed wire drawing lines, offering both precision and efficiency without compromising accuracy.

These advantages make diamond dies for wire drawing a preferred solution for manufacturers seeking long-term cost-effectiveness, precision, and productivity.