Nano Drawing Die

The Nano drawing die is a high-performance tool designed for manufacturing ultra-fine wires or fibers, typically at the nanometer or micrometer scale. It is also an advanced solution for drawing large-diameter cables and wires, offering a perfect balance between durability and precision. With a special nano-coating, this die delivers significantly enhanced wear resistance and a much smoother drawing surface compared to traditional dies. Make the nano-coated die with extended service life and consistent, high-quality output.

Nano Die Hole Sizes

Our nano wire drawing dies are fully stocked and available for immediate delivery.

Features

- Saves conductive wire and cable materials

- Reduces energy consumption

- Long machine uptime

- Excellent wire and cable surface finish

- Long diameter stability

Applications

- Copper, aluminum, and other non-ferrous wires (commonly used in electrical cables)

- Steel and stainless steel wire (including welding wires and high-carbon wires), often without needing special lubrication thanks to the die’s superb surface finish.

Juxin Nano Die Technology

Juxin’s nano dies feature a high-grade tungsten carbide core coated with a nanocrystalline diamond layer using Chemical Vapor Deposition (CVD). This nano-scale diamond coating achieves an exceptional hardness of around 10,000 Vickers, significantly surpassing that of standard carbide and even polycrystalline diamond (PCD) dies. As a result, nano wire dies offer outstanding wear resistance and a much smoother drawing surface. Unlike conventional tungsten carbide or PCD dies, nano drawing dies maintain their inner diameter with virtually no enlargement, even during extended production runs. Taking advantage of the nano-coated die’s superior properties, it ensures extended die life, enhanced surface finish, and consistent wire dimensions throughout the entire drawing process.

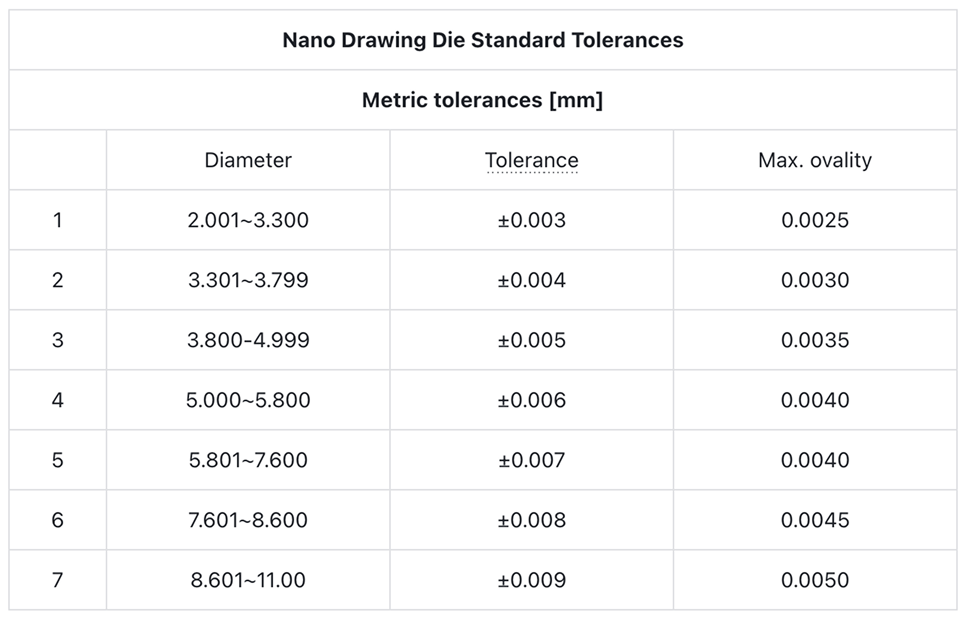

Technical Specifications

*Available size range: 0.05–11mm (We support customization in feeding materials)

Material:

Each nano die features a toughened tungsten-carbide core with a nanocrystalline diamond coating applied to the inner drawing surface. For mounting stability, the die is typically enclosed in a steel outer ring. This construction enhances the performance and durability of nano wire drawing dies, making them ideal for high-precision cable drawing applications

Coating Type:

The inner surface of the nano wire drawing die is treated with a Chemical Vapor Deposition (CVD)-applied nanocrystalline diamond layer, composed of micro- and nano-scale diamond grains. Nano diamond coated die achieves exceptional hardness, typically around 10,000 Vickers (HV) and outstanding wear resistance. The coating thickness, often around 30 μm, is engineered for durability and polished to a mirror-like finish, delivering superior performance in cable drawing die operations. These nano dies deliver consistent wire dimensions, extended die life, and an exceptionally smooth wire surface throughout the entire drawing process.

FAQs

1. What is nano wire drawing die?

Nano wire drawing dies are specialized tools used to create ultra-fine nanowires and micro cables. These precision nano dies are often coated with advanced nano coatings to enhance durability and extend life. Nano-coated dies enable the precise manufacture of nano-scale wires and are widely used in electronics, medical devices, and high-performance cables.

2. What is the advantages and disadvantages of nano coated die?

Advantages of Nano Coated Dies:

Extreme Hardness & Wear Resistance: Nano dies with nano coatings provide exceptional hardness, making the die much more durable than conventional coatings.

Longer Lifespan: Due to reduced wear, nano coated dies last significantly longer, lowering replacement frequency and maintenance costs.

Superior Surface Finish: Produces wires with a smoother and shinier surface, which is important in industries like electronics and medical where precision is critical.

Better Lubricity: The nano coating helps reduce friction between the wire and the die, which minimizes heat generation and improves drawing speed.

High Dimensional Accuracy: Maintains tight tolerances over long production runs, helping ensure consistent wire diameter.

Suitable for Difficult Materials: nano wire dies are ideal for drawing hard-to-process materials like stainless steel, tungsten, or titanium wires.

Disadvantages of Nano wire drawing Dies:

High Initial Cost: Nano drawing dies are more expensive upfront compared to traditional tungsten carbide or standard PCD dies.

Not Always Cost-Effective for Low-Volume: If you’re running short production batches, the higher cost may not be justified compared to cheaper alternatives.

Coating Delamination Risk: In rare cases, improper use or extreme conditions might cause the coating to peel off, especially if the nano coating die isn’t well-maintained.

Place your RFQ request online to see how our Nano Drawing Dies can help improve the quality of your wire

Place your RFQ request online to see how our Nano Drawing Dies can help improve the quality of your wire