Eliminate Wire Defects &

Guarantee 99.9 % Fault-Free Coils

Install wire testing equipment to catch 99.9% surface flaws, dimensional accuracy, and coating integrity simultaneously during manufacturing.

multi-functional detection system

You can install those devices separately or in combination.

Watch the video of our test equipment for wire and cable to learn more about its functions, technology, and how it detects 99.9% of surface flaws.

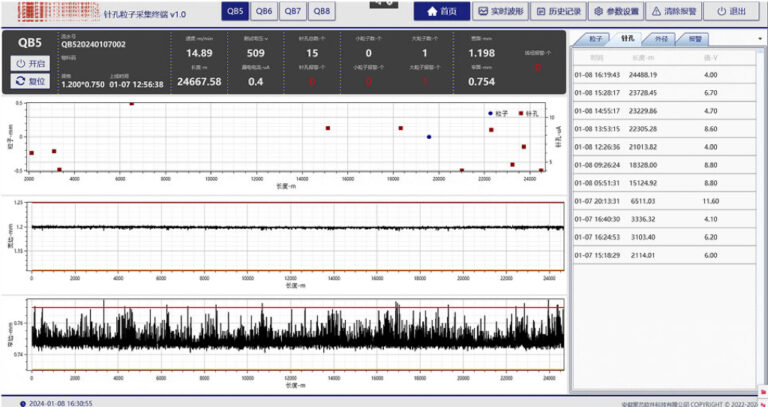

System Interface And Detection Results

System Interface with

Detailed List of Defects

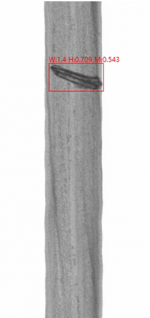

The Scratches on

Superconducting Wire

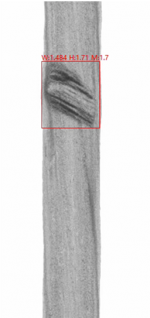

The Dents on

Superconducting Wire

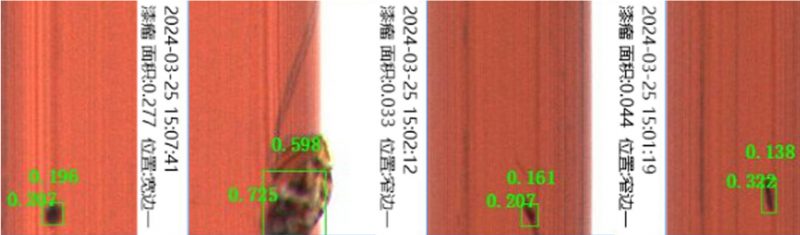

The Surface Bead

on Enamelled Wire

Flat Wire Defect Detection System

Wire Surface Detector for Enameled Flat Wires

The Interface of Pinhole Particle Detection Software

The Interface of Pinhole Particle Detection Software

Wire Surface Detector

High-performance wire testing equipment with automation, real-time monitoring, and easy setup to ensure flawless surface quality in your wire and cable production.

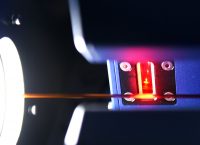

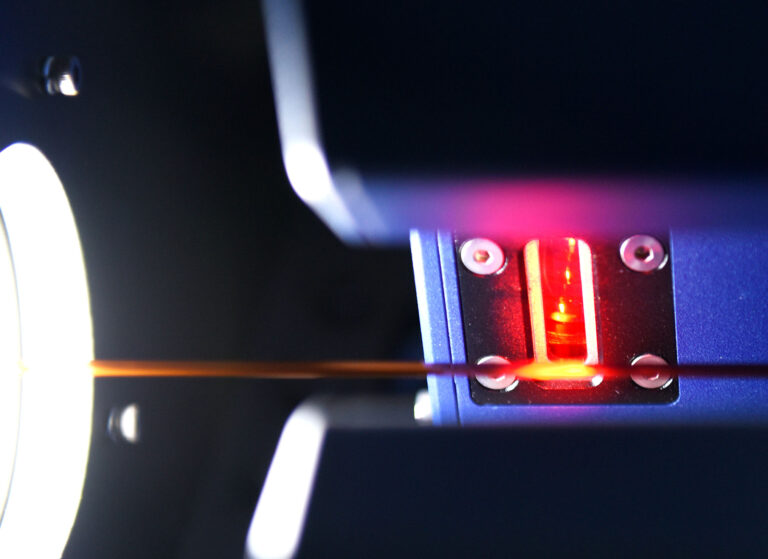

1. High Voltage Pin Holes Detector

The High Voltage Test Equipment is a high-efficiency inspection device designed to identify micro-defects (e.g., pinholes, cracks, breakpoints) in coatings or insulation layers. Utilizing high-voltage discharge technology, it scans material surfaces with a high-voltage electrode to accurately detect invisible micro-defects. Widely applied in coated wires, films, tubing, and related industries.

Technical Specifications

- Detection Voltage Range: 0.5kV – 30kV (adjustable)

- Detection Speed: 0.5 – 5m/s

- Minimum Detectable Defect Size: 10µm

- Compatible Materials: Plastics, rubber, coated metals, composites

- Alert Modes: Audible & visual alarms, data storage, PLC signal output

- Operation: Local control + cloud-based historical data storage & analysis

- Communication Interfaces: RS485, Ethernet, Modbus

Key Features

- High Sensitivity:

High voltage test equipment detects micro pinholes and cracks to enhance product quality.

- Non-Contact Inspection: Prevents material damage during testing.

- Smart Control: Integrated with automated test systems, it supports remote monitoring, automated alerts, and data analytics.

- High Compatibility:

Functions as both a cable wire tester and cable quality tester, adapting to various coatings and materials.

Technical Specifications

Ideal for quality inspection in:

▸ Wire & cable

▸ Coated materials

▸ Plastic pipelines

▸ Films

▸ Metal anti-corrosion coatings

▸ Related industries

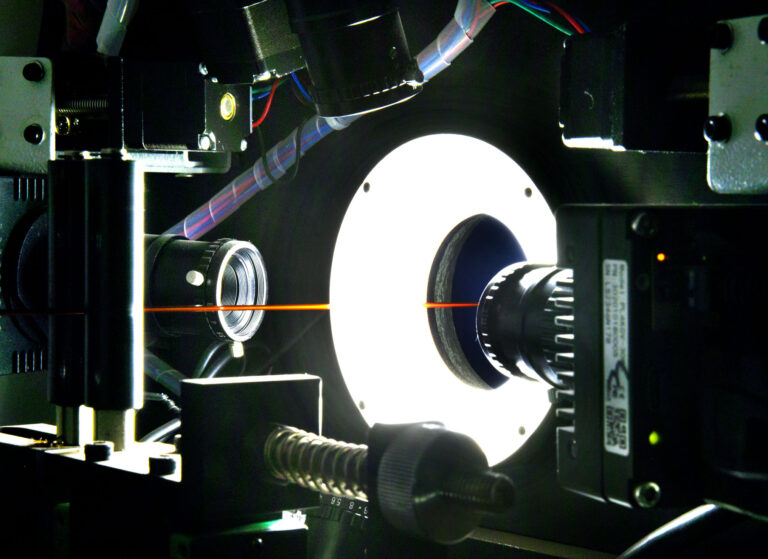

2. CCD Camera Defects Detector

The visual defect inspection system utilizes high-definition CCD cameras and intelligent image processing technology to enable online detection of material surface defects such as scratches, dents, contamination, and cracks. Integrated into automated test systems, it operates at high speeds and applies AI algorithms for intelligent defect classification, significantly improving production efficiency and product quality. This solution is ideal for wire cable and related products, serving as a powerful cable tester for visual quality control across various manufacturing lines.

Technical Specifications

- Camera Resolution: 5MP – 20MP

- Detection Accuracy: Identifies defects as small as 0.01mm

- Detection Speed: Up to 300m/min

- Light Source: Multi-angle LED lighting, coaxial illumination

- Data Analysis: AI deep learning algorithms for automatic defect classification

- Alert Modes: PLC signal output, audible/visual alarms, data logging

- Operation: Local interface + cloud-based historical data storage & analysis

Key Features

- High Precision:

This advanced wire surface detector Detects diverse surface defects, including micro-scratches, foreign particles, and contamination. - AI-Driven Accuracy: Deep learning technology improves defect recognition and reduces false positives.

- High-Speed Performance:

Designed for modern manufacturing, it integrates seamlessly with high-speed wire cable and cable tester lines without requiring production downtime. - Modular Flexibility: Supports integration with industrial cameras, high-voltage pinhole detection, and laser inspection for diverse production environments.

Applications

Key application industries:

▸ Wires/cables

▸ Metals ▸ Glass

▸ Plastic films

▸ PCB

▸ Ceramics

▸ Textiles

3. Particle and Size Detector

The wire surface detector is designed to identify surface particles, dimensional deviations, and shape anomalies on wire and cable materials, ensuring compliance with strict production standards. As part of an integrated wire testing equipment solution, it utilizes high-precision optical sensors or laser measurement technology to perform real-time inspection of moving materials on production lines.

Technical Specifications

- Particle Size Range: 1µm – 5mm

- Dimensional Accuracy: ±0.001mm

- Detection Speed: Up to 600m/min

- Optical System: High-precision laser + AI algorithms

- Data Analysis: Real-time statistics, automatic classification, trend analysis

- Alert System: Audible/visual alarms, PLC output, data storage

- Communication Interfaces: RS485, Ethernet, Modbus

Key Features

- High Precision: Micron-level accuracy ensures product quality

- Non-Contact Inspection: Prevents material contamination or damage

- Smart Analytics: Built-in automated test systems provide data visualization, trend analysis, and closed-loop process control

- Versatility: Adaptable to a wide range of materials, making it a flexible wire cable tester for both standard and custom profiles

Applications

Widely used in:

▸ Wire and cable

▸ Fiber optics

▸ Precision electronics

▸ Thin-film coatings

▸ Semiconductors

▸ Automotive components

Place your RFQ request online to see how our Detection Equipment can help improve the quality of your wire

Place your RFQ request online to see how our Detection Equipment can help improve the quality of your wire