Compacting die, Bunching & Stranding Die

Juxin precision-engineered compacting dies, bunching dies, and stranding dies guide, compact, and shape multiple wire strands into cohesive conductors with ultra-low surface friction for smooth wire finishes. Essential for producing high-quality power cables, stranded wire, and litz wire, our PCD compacting dies and power cable stranding dies ensure superior performance in wire drawing applications.

Compacting Die Hole Sizes

Available: 0.1mm to 11.0mm

We maintain full stock of wire compacting dies for immediate delivery.

Complete Production Process

Juxin Dies provides complete end-to-end die production capabilities covering the entire wire manufacturing process, including bunching, stranding, and compacting. For medium-voltage power cable production, our process begins with bundling fine copper wires using bunching dies, progresses to layered stranding with stranding dies, and completes with high-density conductor formation through compacting dies.

Bunching:

Juxin’s bunching die efficiently twists multiple wires for flexible cables without geometric constraints.

Stranding:

Our power cable stranding dies arrange wires in precise concentric or rope patterns for optimal performance, enhancing both mechanical and electrical properties.

Compacting:

A wire compacting die reduces the diameter of stranded conductors for maximum conductivity and space savings, achieving higher conductivity and improved space efficiency.

Wire Compacting Die Main Feature

- Low surface friction

- Smooth wire surface

- Outstanding efficiency and premium cable output

Advantages of Wire Compacting Die

By compressing wire strands into a tighter formation, compacting dies offer several significant advantages:

Higher conductor density: A wire compacting die minimizes gaps between strands, resulting in improved electrical conductivity and increased mechanical strength.

Smaller cable diameter: Using a compacting die helps reduce the overall cable size, which saves on insulation material and allows for easier cable handling and installation.

Better surface smoothness: Wire compacting dies ensure a more uniform, round surface, reducing friction during installation and enhancing the cable’s appearance.

Improved flexibility and fatigue resistance: Cables processed with compacting dies perform better in dynamic environments, with greater resistance to bending and vibration.

Enhanced manufacturing efficiency: A high-quality compacting die ensures consistent compaction and long service life, reducing downtime and increasing productivity.

We offer 3 material options to produce compacting, bunching, and stranding die:

Polycrystalline Diamond (PCD):

PCD compacting die offers exceptional wear resistance and longevity, ideal for high-volume production.

Tungsten Carbide (TC):

Wire compacting die provides a cost-effective solution with good durability for various applications.

Nano Diamond Coated Dies (NDCD):

Combines the toughness of tungsten carbide with a diamond coating for enhanced performance and die life.

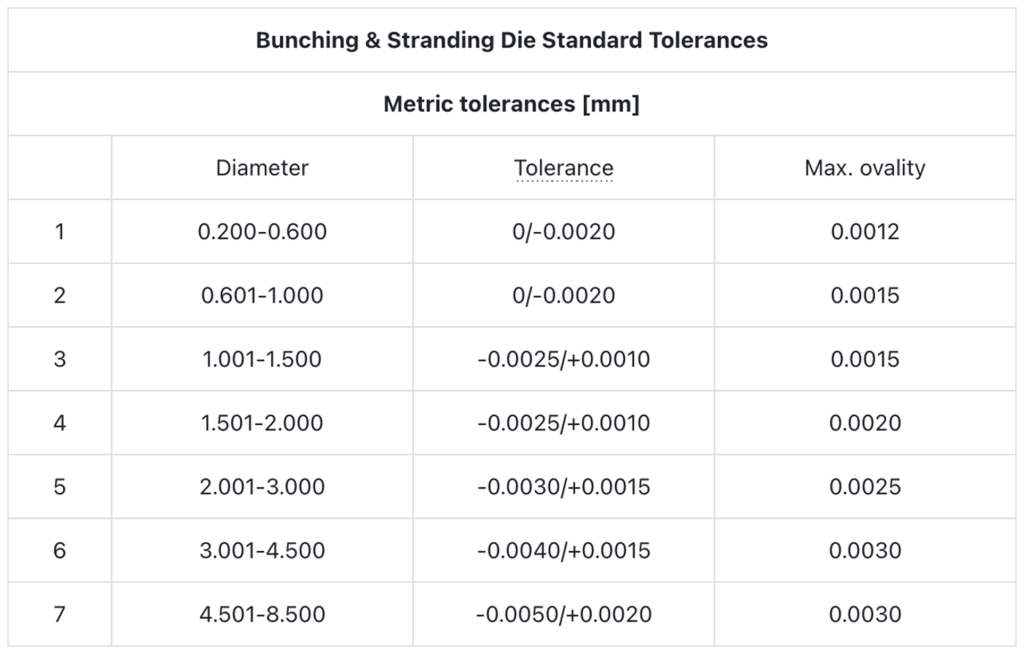

Specifications

*Available size range: 0.05–11mm (We support customization in feeding materials)

Surface Finish:

Mirror-polished for minimal friction and superior wire quality

Bearing Length:

Optimized for concentricity and strand stability

FAQs

1. What is the purpose of a wire compacting die?

A wire compacting die is used to reduce the overall diameter of stranded or bunched wires by compressing them into a more compact shape. This process increases the conductor’s density, enhances mechanical strength, and reduces insulation thickness requirements. Compacting die results in a lighter, smaller, and more efficient cable in terms of performance.

2. What’s the difference between a bunching die and a stranding die?

A bunching die is typically used in high-speed bunching machines to guide and slightly compact multiple fine wires into a round bundle. A stranding die, on the other hand, is used in stranding machines to shape, align, and sometimes compact larger wire bundles (e.g., in power cables), ensuring uniform conductor geometry and consistent cable performance.

3. Why do we recommend you choose a PCD compacting die over traditional tungsten carbide dies?

PCD compacting dies offer significantly higher wear resistance, longer service life, and better surface finish than traditional tungsten carbide dies. Compacting dies with PCD are ideal for continuous production environments, such as wire drawing and compacting for power cables, where precision, durability, and consistency are critical.

4. What role do Power Cable Stranding Dies play in high-voltage cable manufacturing?

Power Cable Stranding Dies are essential in aligning and compacting multiple conductor strands into a unified, stable structure. In high-voltage cable production, these stranding die to ensure optimal conductor roundness, reduce voids between strands, and help maintain uniform electrical performance throughout the cable length.

Place your RFQ request online to see how our Bunching & Stranding Die can help improve the quality of your wire

Place your RFQ request online to see how our Bunching & Stranding Die can help improve the quality of your wire